You have had enough of cutting logs the old-fashioned way with an axe and a chopping block but you don’t want to spend money on an expensive log splitter so what are you to do? Well, for the more adept of DIY enthusiasts, one option is to build your own.

Constructing your own homemade log splitter can be a challenge, and some people might not be sure where to start. To help you out, we’ve scoured the internet to see what other people have been trying – and here is a roundup of the homemade log splitter plans we unearthed.

Table of Contents

1. The Unicorn Log Splitter

This guy doesn’t include many written instructions but it’s clear what he’s trying to do and how his splitter works from the images.

He’s rigged up an engine that turns a corkscrew-like head. This corkscrew – the unicorn’s “horn” – drills itself into the log, splitting it as it goes.

If you can make the corkscrew head, the rest of the work is easy. There is a diagram included for how to make the corkscrew – this part is labeled in Russian, although it’s not too difficult to understand the general idea.

We love the whole setup – it’s creative and ingenious as well as being relatively safe. It looks like a fast and effective way to deal with most types of logs and could be something worth trying if you want to build a splitter of your own.

2. The Wheel of Debt

If you are looking to build a log splitter for the lowest cost and mainly from pieces of scrap you probably have lying around, this contraption we found in a YouTube video should be of interest.

The concept is simple – a cutting blade is mounted on a large wheel attached to a gas engine. The engine turns the wheel and logs are placed in the blade’s path to be split.

The advantages of making something like this are clear. The design requires minimal outlay and can easily be adapted to work with whatever materials you have at hand.

However, the disadvantages are also immediately obvious – unless you are extremely careful, this splitter is just a recipe for severed fingers or worse.

Just a moment’s lapse in concentration could easily lead to a serious injury, and we would think twice about building one – but one thing’s for sure, it certainly showcases this guy’s inventiveness.

3. Homemade Manual Wood Splitter – Part I

This idea is from another video on YouTube. The video gives you several examples of how to build the same kind of wood splitter – and also shows how effective it can be.

The concept is simple. You mount the splitting blade on the end of a long arm and use a spring to return the blade to its original position after each use.

Once constructed, it’s easy enough for just about any adult to use. You place the log in the blade’s path and then pull the blade down onto the log with enough force to split it, after which the spring lifts the head back up for another shot.

As far as homemade log splitters go, this one is pretty safe too – although you certainly wouldn’t want to let children operate it.

However, with all the effort required to build and operate it, we aren’t sure that it’s much better than just swinging an axe the old-fashioned way. Perhaps with this creation, at least each impact is less jarring than chopping wood manually.

Anyway, up to you to decide – we just bring you the ideas!

4. Manual Log Splitter – Part II

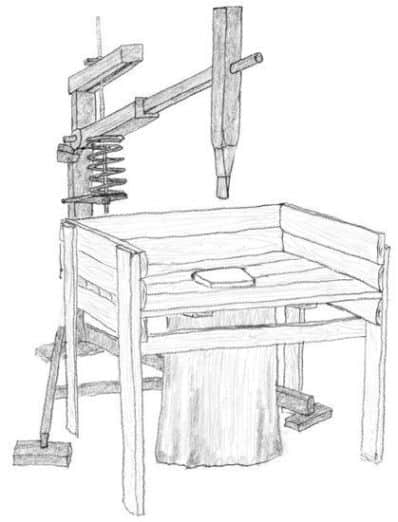

Here we have another log splitter that is very similar to #3 in concept – but this time with some drawings to help you construct it.

Again, you have the blade attached to an arm that is pulled down onto the log to split it. The arm is then returned to the original position by means of a spring.

One way to improve the power of this log splitter, assuming you have a large enough spring, would be to attach a weight to the blade to increase the force when you bring it down onto the log.

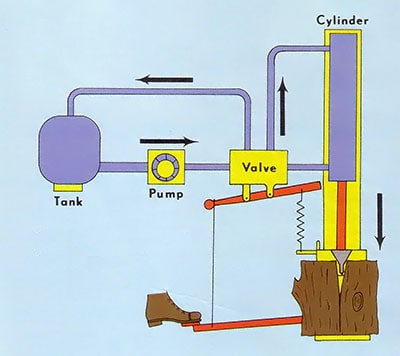

5. DIY Hydraulic Log Splitter

The problem with a lot of DIY log splitter plans is that while they might be relatively easy and inexpensive to make, many give you only questionable levels of performance and reliability.

Not many of them can match a good hydraulic splitter in terms of power and convenience – but this model is different.

Here, this DIY expert shares his plans for making a DIY version of a heavy-duty hydraulic splitter. Since it cuts vertically and not horizontally, he even claims it’s superior to bought splitters since you don’t need to bend and lift as much during the process.

For sure, this machine will take more expertise to build – and the components are likely to cost more than some of the more basic models we’ve mentioned in this roundup – but once it’s ready, it will slice through your logs with ease.

If you think you’re up to the task of building it and you can get hold of the materials, constructing one of these will still be far less expensive than buying a log splitter – so why not give it a go?

6. Small but Powerful DIY Log Splitter

If you don’t quite have the space for something as big and bulky as the log splitter in #5, this smaller version might be a better option.

This guy takes you through the steps that were required to build his homemade splitter. We love the way he uses just anything he can get his hands on – an axle from a Saab 900 or an old beer keg for the hydraulic reservoir for example!

He also explains how the design developed and how he improved his splitter with experimentation and experience.

The result is a splitter that looks very DIY – but that also looks like it works pretty well too. We give this guy top marks for creativity, resourcefulness and skill. Can you make one that works as well using his plan?

7. A Big Splitter to Minimize Lifting

Here we found the details of how somebody who wanted to save his back from the strain of bending and lifting that is normally associated with using a traditional log splitter built a machine to meet his own requirements.

It’s a hefty, sizeable piece of equipment that weighs upwards of 2,000lbs, and if you want to copy it, you’ll have to be ready to spend some money acquiring the components.

However, it will still cost you a lot less than buying a new log splitter and – most importantly – it will do the job you need it to.

Although we can’t be sure of its true capacity, the guy who designed it says he’s never found a log it couldn’t split.

Of course, if you are looking for something for more industrial-scale work, you’ll probably need to look at buying a professional piece of equipment – but if you just need a log splitter for home use, something like this will be more than up to the task.

8. 30-ton Beast from Scandinavia

If you have a love for all things DIY and also have a fondness for raw power and brute force, you’re sure to approve of this Scandinavian monster.

There’s nothing subtle about this machine – it simply uses its huge power to force logs through the blade section, splitting them into several pieces.

You can either line logs up one by one and push them through or deal with whole tree trunks. This is another video we found on YouTube so there are no plans to follow, but if you want to copy the idea, you’ll be able to see what needs to be done.

It’s a big, noisy splitter – but you can see from the video how effective it is at dealing with large amounts of even the toughest wood. In this respect, it is comparable to a large gas log splitter.

If you need to split wood on something like this scale and you don’t mind using something unapologetically crude but brutally effective, constructing something along these lines might be something you’re interested in trying.

9. Self-Proclaimed Redneck Splitter

There’s so much to like about this log splitter. In line with the best DIY projects, it’s extremely simple and made of bits and pieces the designer found lying around as well as a few pieces of salvaged junk.

He claims that apart from the initial stage of constructing the frame, he also didn’t make use of any drawings or written plans, preferring to make it up as he went along.

He includes good photos and clear explanations of the construction process – including details of how his contraption went wrong and what he did to fix it back up.

This guy is obviously a talented DIYer – but we also love his sense of humor too. We enjoyed reading about his “Redneck” foot-operated log splitter – and maybe you’ll enjoy trying to build and use one too.

10. Basic Powered Log Splitter

While this machine is never going to make it as a commercial log splitter, it is simple and cheap to make and will save you from the back-breaking work of swinging an axe.

As with many of these DIY log splitters, you might have to spend a little cash for the basic components, but when you consider that buying a log splitter can cost upwards of $1,000, constructing a machine such as this is still a very economical alternative.

This device generates plenty of power to cut through oak logs sideways, as is demonstrated in the video – although it does seem to crush them somewhat.

However, by using this splitter to split logs along the grain, you can see how it would be extremely effective.

The details of how to put it together are a little lacking on the site, but at least you can see the basics of how it’s done – and if you have a little technical know-how, you should be able to rig up something similar.

11. Attention to detail!

Here’s another one we wanted to include – and for a couple of reasons.

First, in keeping with the best DIY traditions, it’s constructed from scrap and other bits and pieces from around the house so would cost very little to make.

Second, the video is extremely well made. It’s another YouTube video – so no drawings or plans to help you out if you want to copy – but the video is so clear and demonstrates everything you need to do, so there’s hardly any need for anything else.

Third, the end product looks extremely effective. If you want something that will split firewood effortlessly for you at home, this would be an extremely effective machine for doing it.

And finally…we love the attention to detail in making this splitter.

Most of the videos we’ve seen show contraptions made of rusting pieces of metal that look they are about to fall apart – but this guy obviously takes pride in doing the best job he can, even taking the time to give it a coat of paint to make it look the part too.

Check it out – as far as aesthetics go, this one is a clear winner.

A word of warning

Having searched online to see what genius inventions people are coming up with, we feel we should end with a word of caution.

Even bought log splitters can be dangerous pieces of machinery and should be operated with care and attention at all times.

However, some of the things we have seen online – including perhaps one or two we have included in this roundup – are little short of death traps. If you do attempt to make something like this yourself, above all, make sure you put safety first!

After all…fingers, arms and legs are a lot softer than the logs these machines are designed to split.

Ingenious designs that can save you cash

We love DIY and DIYers because of the creativity and ingenuity that machines like this showcase. Some of these plans look highly effective while others seem more dubious. Making your own DIY log splitter can save you a whole lot of cash – but as we’ve already mentioned, make sure your first thought is always for safety.

Don’t forget to pin it!

I’m glad that “Log Splitters” have evolved enough to be horizontal and low profile.

One even hinges on a trailer to be vertically touching the ground for a no lift operation.

But I haven’t yet seen one that hinges with counter weight springs down OVER a log rolled on the ground. The usually stationary end could could also have a splitting maul and easily adjust for a few different lengths. Splitting edges should be 6 or 8″ wide and always stop at 1″ above the ground. You should also add deck plating or a box at the tongue so it won’t depend on the trailer hitch to keep it from flipping when the hydraulic splitter is flipped out.