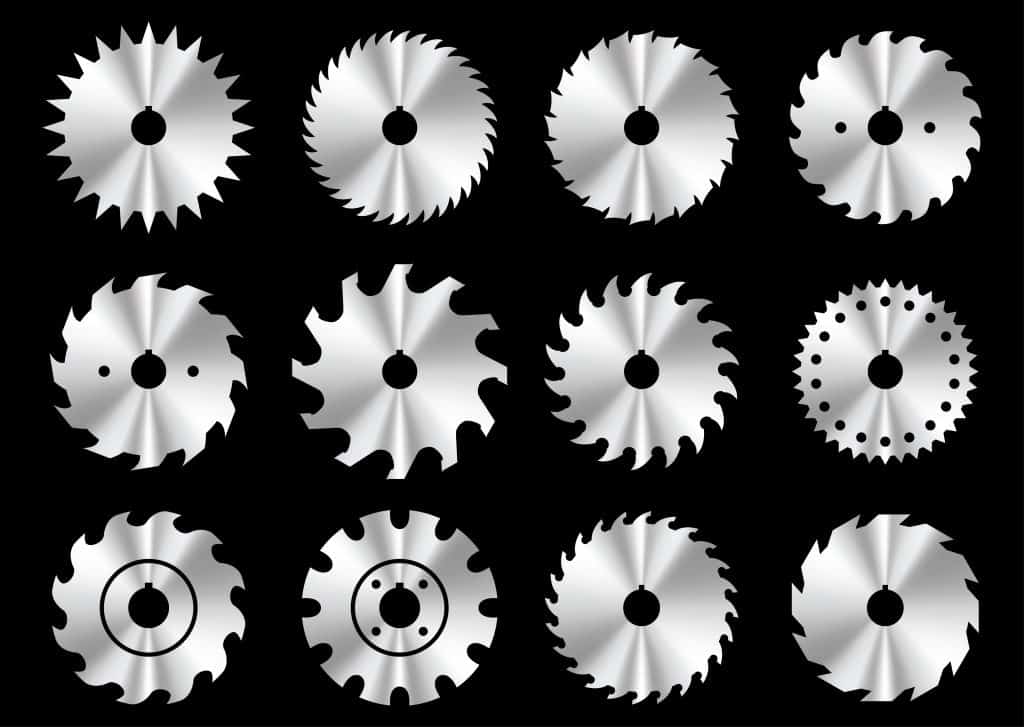

Circular saws are versatile tools that can be used to make a range of cuts in wood, metal, plastic, concrete and more. However, any circular saw is only as good as the blade you use, and it is vital you choose the correct type of blade for the job you are working on.

There are many types of circular saw blade, all designed for specific uses. If you want to know which blade to use for a specific project or are just looking for an overview of the types of blades that exist, here we have all the information you need about circular saw blade types.

Here’s a good video that will give you an introduction to some of the things we’re going to be talking about.

Table of Contents

What factors affect the type of blade you should choose?

There are several factors that affect the type of blade that is most suitable for your project. Here are the most important.

- Material you need to cut

Probably the most important factor that affects the blade you choose is the type of material you need to cut with it.

Many circular saws, including both sidewinders and worm drive saws, are capable of cutting a variety of materials – but it simply won’t work if you use a blade designed for cutting plywood on a slab of granite. Choose a blade that is made for the material you need to cut.

- Type of job

There’s a big difference between making quick, rough cuts on something that will be hidden and making careful, clean cuts on a piece of wood that will be seen. Blades exist for rough cuts and blades exist for finishing. Choose the most appropriate one for what you want to achieve.

- Type of cut

Even when just cutting wood, there are many possible types of cut you might need to make. Blades exist for ripping, crosscutting, cutting dados and many more. We’ll be talking about these in more detail in just a moment.

The different features of a saw blade

Now let’s have a look at the different features of saw blades and how variations make each type better adapted for particular jobs.

- Number of teeth

One of the most obvious features of any circular saw blade that will be immediately recognizable even to someone who has never used a circular saw in their life is the number of teeth.

In general, the fewer the teeth a blade has, the quicker it cuts but also the rougher it cuts. If you want cleaner, more precise cuts, you should choose a blade with more teeth.

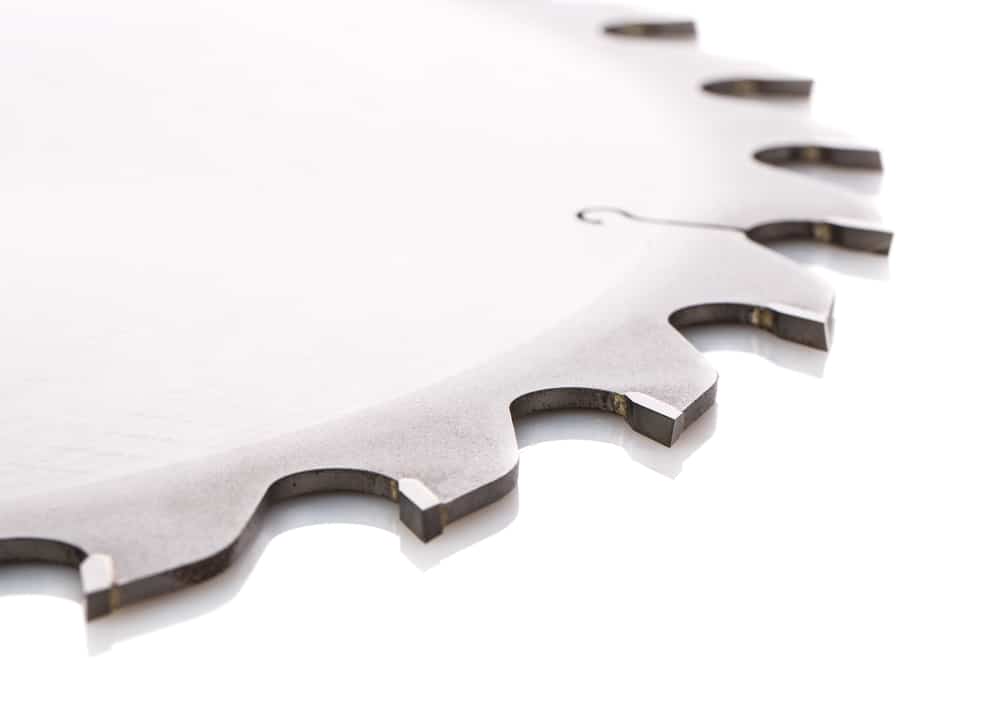

- Gullet

The gullet is the space in between each tooth. Deeper gullets are better at removing larger chips of wood while shallower gullets are more effective at removing finer sawdust from the cut.

- Expansion slot

Some blades include expansion slots. These are designed to let the metal of the blade expand slightly as it heats up, allowing you to continue cutting efficiently.

- Size

Regular circular saw blades are 7 ¼” – but other sizes exist. For example, mini circular saws can have blades of only 4 ½”. This means you need to make sure you choose the right size for your tool.

Different types of blade and their uses

Now let’s have a look at the most common blades and what they are most useful for.

1. Ripping blades

Ripping blades are designed to cut along the grain of the wood. They usually have few teeth, perhaps around 14 to 24, and have a deeper gullet. They are good for making fast, rough cuts.

2. Crosscutting blade

Crosscutting blades are used to cut across the grain of the wood. They have more teeth than a ripping blade as well as a shallower gullet. They cut more slowly but produce a smoother, cleaner result.

3. Plywood blade

Since plywood chips and splinters easily, blades for cutting plywood tend to have far more teeth, usually in the range of 40 or more. These blades are designed for use on fine material and will help minimize splintering of the wood as you cut.

4. Combination/general purpose blades

These blades are somewhere between ripping and crosscutting blades. They are a good choice if you need one blade for a variety of uses, but if you need a blade for a more specific job, you’re better off buying a specialist blade for that application.

5. Finishing blade

Finishing blades are designed for making clean and precise cuts on parts of the wood that will be visible when the job is completed. To achieve this, they have a larger number of teeth and are intended for making extra-smooth cuts that don’t damage the wood.

6. Dado blade

If you need to cut dados, rabbet cuts or grooves, specialist blades exist for this kind of work.

7. Thin kerf blade

The ‘kerf’ refers to the width of the cut, and a thin kerf blade is one that makes an especially narrow cut through the wood. These blades are most commonly used for cutting dimensional lumber.

If you try to use a thin kerf blade on tougher wood, it is likely to flex, making it impossible to cut in a straight line.

8. Treated wood

For treated woods, you should choose a blade with a thicker kerf. This will allow you to cut straight lines more easily.

9. Plastics

Many blades for cutting wood can also be used to cut plastic. However, it is best to choose one with a larger number of teeth – between around 40 and 60 is ideal. This kind of blade is also suitable for cutting soft metals.

10. Masonry blades

Blades for cutting masonry are completely different from woodcutting blades, and the first thing you will notice is that they don’t have any teeth.

They are made of fiberglass-reinforced silicon carbide abrasive and wear away the masonry rather than slice through it like woodcutting blades.

If you are cutting masonry of any kind, this is the only kind of blade that will work.

11. Metal cutting

Specialist blades also exist for cutting metal. Blades that are suitable for cutting most metals, including ferrous and non-ferrous metals, are toothless and feature expansion slots.

Choose the right blade for the job

With so many materials that can be cut with circular saws as well as the range of different types of cut, there is no such thing as a “best” blade, only the most suitable. For the best results, understand which type of blade is best adapted to the job you need to do and choose accordingly.

Don’t forget to pin it!