While table saws may be among the most useful tools in the woodworker’s workshop, they are inarguably also among the most dangerous. One reason for this is the very real possibility of kickback – when the blade sends a piece of wood flying towards the user at high speed.

However, if you know why kickback occurs and understand the precautions to take to minimize the risk, you can significantly reduce the dangers of a serious accident occurring. To help, here are our top 7 kickback prevention tips.

First, understand kickback

One of the main reasons kickback is responsible for so many accidents is that some people don’t understand exactly how or why it occurs – and many others underestimate the danger.

This is why the first step in avoiding it – and avoiding injury – is to understand the mechanics of kickback.

There are two types of kickback. The first – slightly less dangerous – type is when a small off-cut catches on the blade and is thrown up into the air. We will talk about how to reduce the risk of this later.

The second type is more dangerous and involves the whole workpiece catching on the blade and being thrown with great violence back at the user. This happens for two possible reasons.

The most common way this can happen is when, as the wood is pushed along the table saw fence, the leading end begins to rotate and drifts away from the fence across the back of the blade.

As this happens, the piece is caught by the teeth of the spinning blade and is thrown up into the air.

The second possibility is that pressure causes the kerf to tighten around the back of the blade – with the same result.

Don’t underestimate the power and the speed

What many people don’t fully understand is that due to the speed at which the blade is spinning, when kickback occurs, it happens so quickly that you have no time to react. There is simply no way for you to control it or move out of the way.

Another important thing to understand is that due to the rotational force on the wood as the teeth bite, the kickback may also draw your hand onto the table saw blade – meaning there is a danger of a serious cut as well as the danger of being hit by flying stock.

If you’re still in any doubt, check out this video that shows exactly what happens – and the frightening speed and power it can generate.

Here are our tips for avoiding kickback and minimizing the risk of injury – and they apply to any kind of table saw, from the smallest jobsite table saws to larger models like contractor table saws, hybrid table saws, and cabinet table saws.

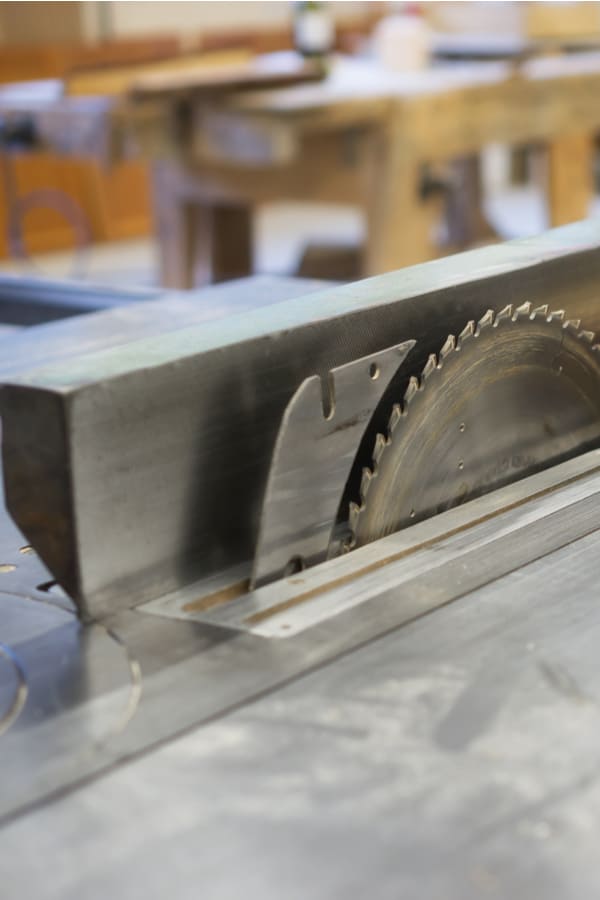

1. Use a riving knife

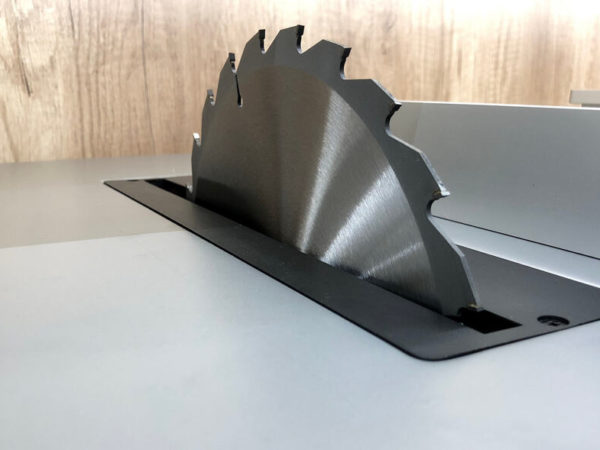

Having understood why kickback happens, one of the most effective ways of minimizing the risk is to always use a riving knife. This is a curved attachment that locks on at back of the blade and that is designed to prevent the stock drifting onto the teeth.

Riving knives closely follow the curvature of the blade and move with the blade as you adjust it up or down – and side to side when you need to cut bevels. They are such an effective way of reducing the risk of kickback that they are now required by law on all table saws sold in the US.

If you have a riving knife, make sure it is fitted whenever you use your table saw – unless you are making a special kind of cut that requires it to be removed.

2. Use a splitter

Splitters work in a similar way to riving knives to prevent stock drifting onto the teeth at the back of the blade.

They don’t move with the blade and need to be removed when making non-through cuts.

Since they are smaller and don’t curve with the blade, they are less effective at preventing the stock from catching in the teeth.

However, they are still much better than having no protection at all and are also easy to fit – so if you don’t have a riving knife, you should always use a splitter.

3. Make sure your fence is perfectly parallel to the blade

A fence that is not aligned perfectly with the blade can greatly increase the risk of kickback by angling the movement of the stock towards the back of the blade.

Reduce the risk by ensuring the fence is set perfectly parallel to the blade – and if perfect accuracy is not possible, it is better for the degree of error to angle the piece away from the blade rather than towards it as you push it through.

4. Adopt the correct position

You should never stand directly in line with the blade of a table saw as you work. Instead, make sure you stand to the side as you feed the stock into the blade. This will mean that, should a kickback occur, you will not be in the danger zone and will not be hit.

This is also important if kickback occurs when off-cuts are thrown up – again, it’s best not to be standing in the way when it happens.

5. Use a push stick

A push stick is used to push smaller pieces of stock onto the blade rather than using your hand. This avoids your hand coming too close to the blade as you work.

This minimizes the risk of accidentally pushing your hand onto the blade but also means that if a kickback occurs, your hand won’t be drawn onto the blade, avoiding a potentially serious injury.

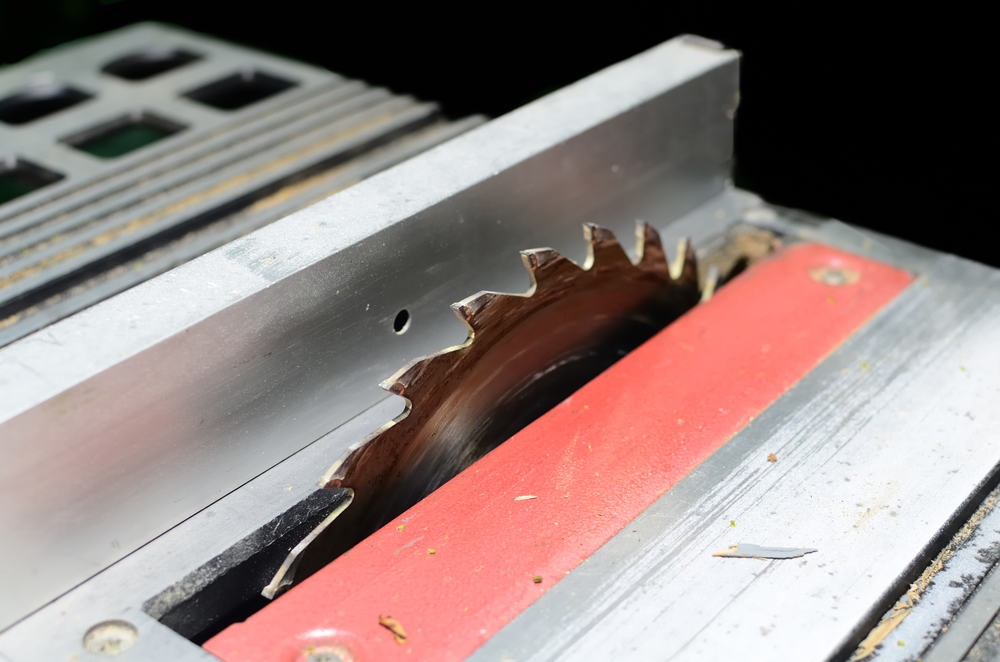

6. Use a sharp blade

Using a blunt blade can increase the chances of the stock being caught on the teeth and thrown up at you. For this reason, you should avoid working with a dull blade.

7. Keep your table clear of off-cuts

To minimize the risk of small pieces of wood being caught on the blade and thrown up at you, you should always keep your table clear of debris. After making each cut, make sure you clear away the waste before making the next cut.

Don’t underestimate kickback and always put safety first

Table saws are dangerous tools, and one of the biggest risks is kickback – and as we have mentioned, part of the danger comes from people misunderstanding how kickback occurs or underestimating how quickly it can happen.

The first step in minimizing the risk is fully understanding kickback. With this knowledge, you can then take the necessary steps and precautions to minimize the chances of it happening and avoiding injury if it does.

Don’t forget to pin it!