A good table saw is one of the most important tools in the woodworking workshop, and the key to getting the best from yours is keeping it well maintained and properly tuned.

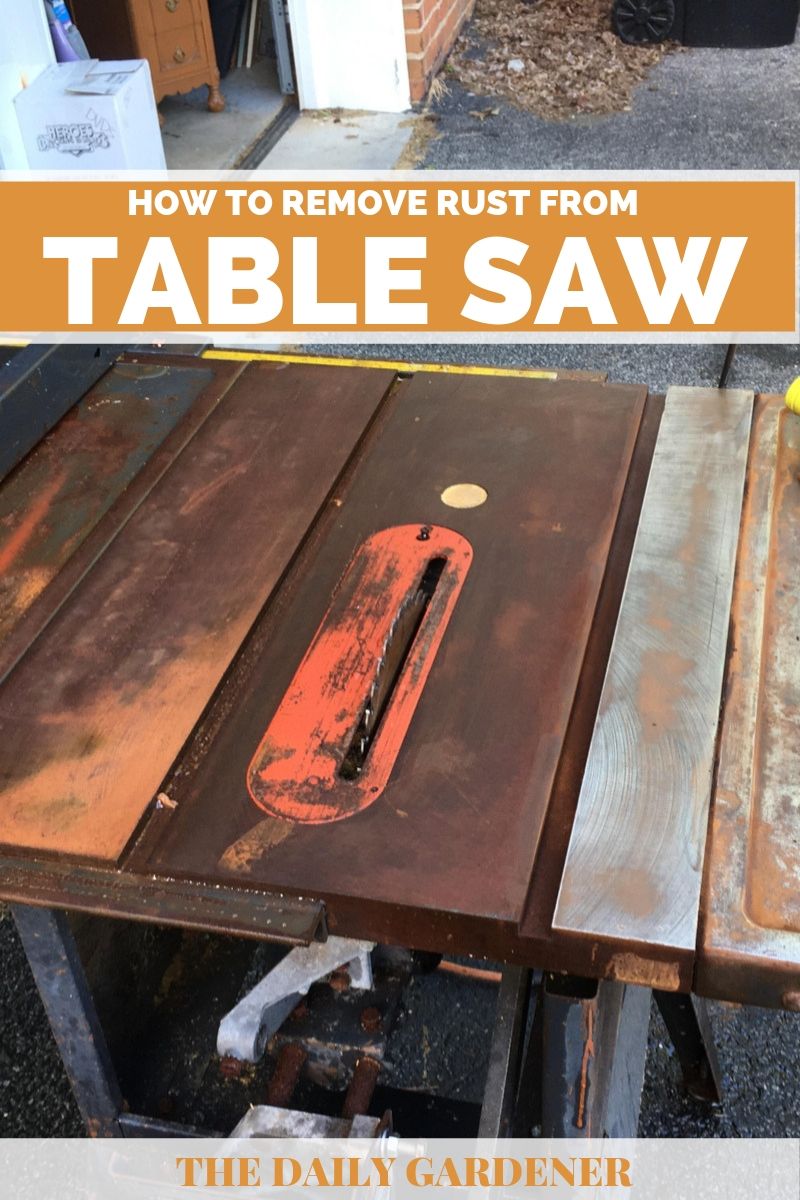

Some table saws, especially those with cast-iron tops, can be susceptible to rust. If you neglect your tool or fail to protect it adequately, you may find that rust quickly develops – and if that happens, here is our guide on how to remove dust from a table saw.

Table of Contents

Asses the severity

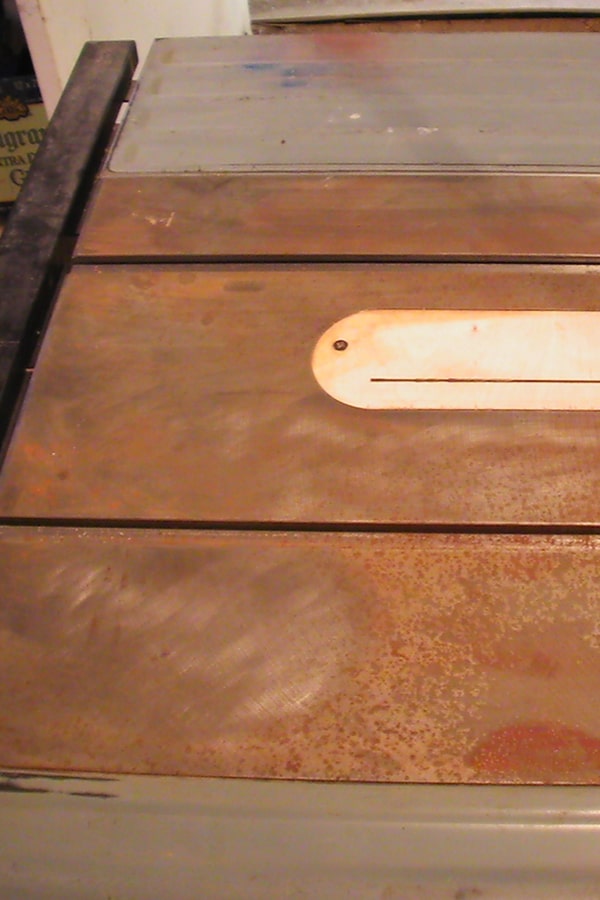

The first thing to do is to assess how serious the rust is. If you catch it early enough, the rusting will be only superficial and much easier to remove. If, on the other hand, the rusting is deep and significant, the removal operation is likely to be more involved.

In extreme cases, the rust may be so severe that there is nothing you can do. A deeply pitted, damaged table will not yield satisfactory results – and if this is the case, you might be better off simply buying a new one.

Assessing the extent of the rust will allow you to determine what to do next.

If the rusting is only light…

If you catch it in time and the rusting is only light, you will be able to deal with it relatively easily.

To remove superficial rust, you will need a synthetic scouring pad or some 400-grit wet/dry sandpaper and some kind of lubricant – mineral oil or WD-40 would both be suitable for this.

To remove the rust, simply apply the lubricant with a rag and scrub with the sandpaper or scouring pad. Keep working until all the rust has gone, taking care not to miss any slots or edges.

Make sure no rust is left – if you miss any, it will quickly begin to spread again.

If the rusting is more severe…

If the rusting is more severe, you will need to prepare for a more intense operation. Note that the process will be the same for any kind of table saw, including a jobsite table saw, a contractor table saw, a hybrid table saw or a cabinet table saw.

First, prepare the table saw by removing the blade insert, table saw blade, table saw fence and any other accessories to give yourself good access.

Next, take a small knife or metal brush and work on any encrusted areas of rust to knock off the worst. Make sure you don’t scratch or damage the surface – the idea is just to remove any lumps of rust that have developed.

Once you have removed the worst of the rust, you will need to apply a chemical rust stripper, often known as naval jelly.

This is a strong chemical product, so make sure you wear protective gloves and eyewear and also ensure that you are working in a well-ventilated area – open all windows and doors and use a fan if you have one.

Naval jelly can be bought at your local hardware store. Apply a good coat evenly over the surface of your table and leave it to act – read the instructions on the bottle to find out details for how this should be done.

After the naval jelly has done its thing…

Wipe off the naval jelly with a rag – the rust will come off as a kind of dirty grime. Once it’s removed, inspect the surface. You may find that with especially heavy rusting, you might need to repeat the process a few times to achieve the desired result.

If you are happy with the surface, you can now wipe it clean and rinse with water. You may find you need to work on a few stubborn spots with 400-grit wet/dry sandpaper or a synthetic scouring pad as we mentioned for less severe rust.

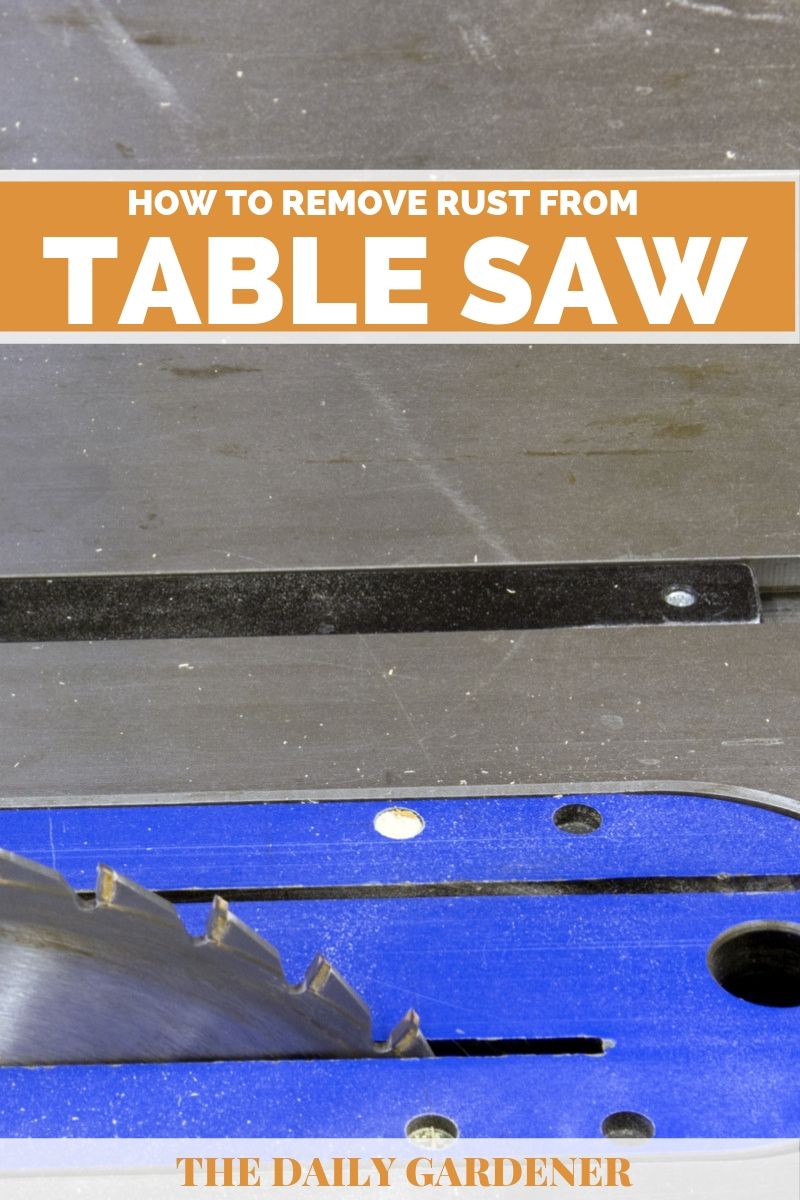

Prevent it from happening again

When you have removed the rust, you will want to make sure it can’t come back. Here’s what to do next to prevent the problem from recurring.

As we have already mentioned, make sure no traces of rust are left after you finish cleaning the table since any spots of rust you miss will trigger a new spread of rust.

Once you are sure there is no rust left, dry the surface and treat it with a protective product.

There are several options for this. Popular choices are T-9 and Slipit – which can be picked up easily from your local hardware store. You can also use WD-40, paraffin wax or paste wax.

One product you should avoid using, however, is car paste wax. This usually contains silicone, which can find its way into the pores of any wood you are cutting and will cause problems later when you try to apply a finish to the wood.

Similarly, if you use WD-40, don’t use the table saw immediately after you apply the product. As with products containing silicone, it will cause trouble when you try to apply a finish to your wood later.

A further advantage of applying something like paraffin wax or paste wax is that it will lubricate the surface, making it easier to work with your stock and giving you even better results.

An old-fashioned technique

Some people might suggest a more “traditional” method for protecting the surface of a table. Before applying the protective product, rub in a layer of distilled vinegar and leave it to dry.

The idea is that it will help clear off any final lingering rust you might have missed while also helping to prevent the rust from returning.

After the vinegar has dried, you still need to apply a layer of paraffin wax, paste wax or other protective product before the job is done.

Keep it well maintained and rust-free

The best method for keeping a table saw free of rust is to regularly apply a protective product and to clean it as soon as possible if any signs of rust develop.

However, if you do let your table saw become rusty, by following the steps and using the techniques we have talked about here, you should be able to return your table saw to good working order without too much trouble.

Don’t forget to pin it!